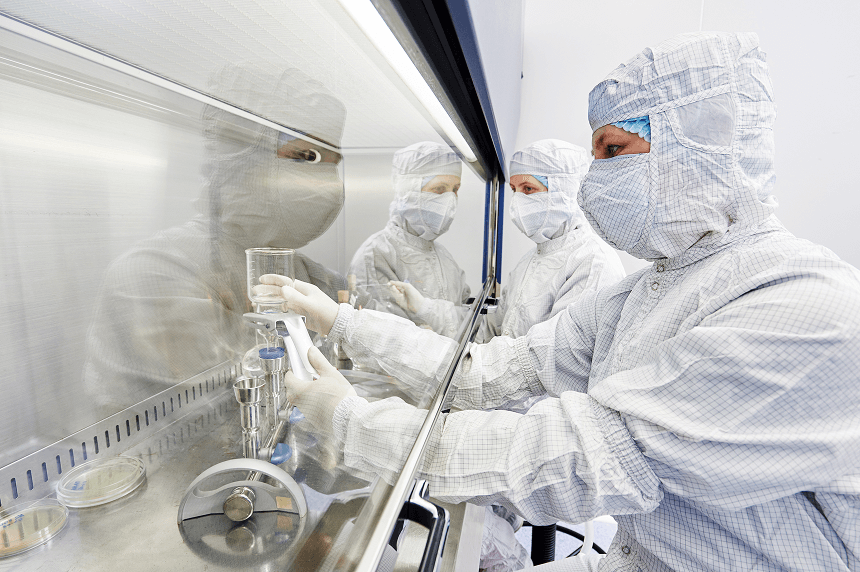

Taking USP <797> Best Practices into the New Year: Resolutions for Sterile Compounding Success

Understand how to design effective media-fill tests that accurately simulate real-world sterile compounding workflows and verify personnel competency across both non-HD and HD environments. This article breaks down the key elements, testing schedules, and documentation practices needed to build a reliable, compliant, and sustainable MFT program. Read more